Sulzer Chemtech AG

General description of the company

![]() Sulzer Chemtech, a division of Sulzer Ltd, offers innovative separation and mixing technology, process solutions, and field services for the oil and gas, hydrocarbon, and chemical processing industry. Our advanced and economical solutions set standards in the field of mass transfer and static mixing. We develop, design and produce mass transfer equipment and can offer solutions for all our customers’ separation problems.

Sulzer Chemtech, a division of Sulzer Ltd, offers innovative separation and mixing technology, process solutions, and field services for the oil and gas, hydrocarbon, and chemical processing industry. Our advanced and economical solutions set standards in the field of mass transfer and static mixing. We develop, design and produce mass transfer equipment and can offer solutions for all our customers’ separation problems.

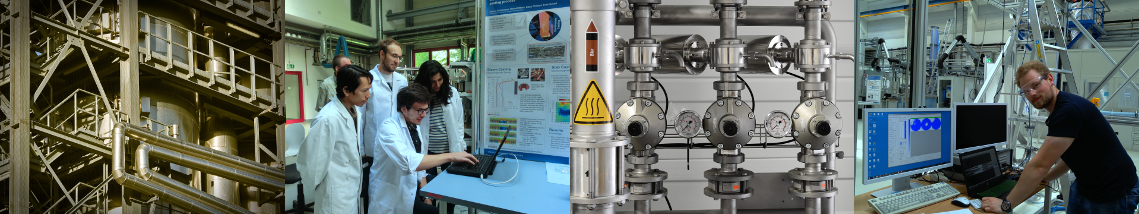

Our portfolio includes state-of-the-art products for distillation, absorption, stripping, evaporation, phase separation, crystallization, and liquid-liquid extraction. More specifically, Sulzer Chemtech is the leading supplier of technology for solvent-free melt crystallization. We are the only company offering equipment for static, falling film, and suspension crystallization as well as for freeze concentration. In addition, we offer bench-scale and pilot trials for process development at our test center in Allschwil covering the whole range of unit operations.

Our analytical laboratory equipment enables us to measure and monitor the relevant qualitative and quantitative parameters to meet the required specifications. Such data obtained from pilot trials are mandatory for the design and sizing of commercial crystallization units. As a result, a detailed proposal can be submitted, which will include a preliminary process flow diagram, an equipment list and plant performance data.

Over the years, Sulzer Chemtech has supported various PhD projects of partner universities, such as the Kuwait Institute for Scientific Rersearch (KISR), the Swansea University (UK), the University of Erlangen (D) and the Martin Luther University Halle-Wittenberg (D), and developed specific know-how about the purification of various organic and inorganic substances by melt crystallization.

Role in TOMOCON

- Hosting two PhD students (ESR 11 and 13) in our company, giving them access to our world-class crystallization facilities in Allschwil and train them in industrial crystallization processes

- Provide industrial Co-supervision to ESR 11

- Become member of the Advisory Board and give consultancy in the fields of crystallization, fluid separation (gravitational, distillation, extraction), chemical process equipment and control as well as process measurement and analysis techniques and process modeling

- Assist and counsel students in the preparation and conduction of experimental work

- Participate in technical meetings and offer an industrial-perspective training (lecture, presentations) at summer schools

- Offer a company visit, if applicable

Key Persons

Dr. Claudia Pudack: Co-supervision of ESR 11; Training of ESR 11 and 13 in industrial crystallization processes

Dr. Manfred Stepanski: Co-supervision of ESR 11; Training of ESR 11 and 13 in industrial crystallization processes