Qualification of Electrical Resistance Tomography (ERT) for real-time control of inline fluid separation

Fellow: Muhammad Awais Sattar (ESR 10)

Host: Lodz University of Technology (Poland)

Main Supervisor: Prof. Dr. hab. Laurent Babout

Background:

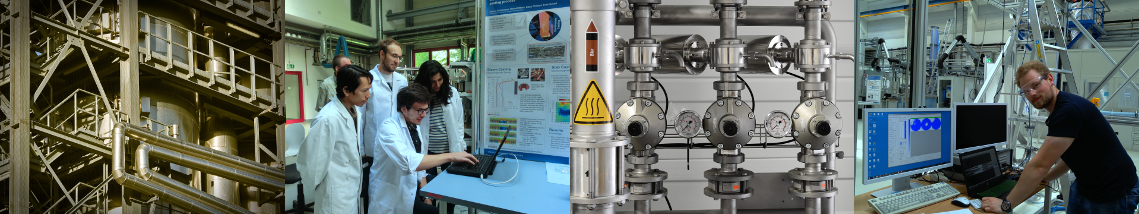

Inline fluid separation is an efficient way to split fluid mixtures via density-based centrifugal separation in a pipe. The doctoral student shall develop an electrical resistance tomography (ERT) imaging sensor technology towards integration into control of inline liquid/gas separation systems. More specifically, the project aims at qualifying electrical resistance tomography as a non-invasive tomographic measurement method to extract geometrical characteristics of the hollow vortex (shape, size and lateral position) in real time to allow actuator control for phase extraction and provide control variables for actuation control. This comprises configuration and development of robust sensor front-ends with 2D/3D electrode layouts as well as fast data processing software based on observe-and-react architecture to control flow behaviour. The work comprises fundamental scientific analyses, engineering design, software development and technical demonstration, together with groups at Helmholtz-Zentrum Dresden-Rossendorf – HZDR (Germany), Institut National Polytechnique de Toulouse – INPT (France), Technische Universiteit Delft – TUD (The Netherlands) and different industry partners.

Research Activities / Objectives:

- Assess different sensor morphologies (multi-layer 2D, 3D);

- Design an electrical sensing system and dedicated data acquisition, processing and analysis protocols that aim at unambiguously obtains phase fraction distribution and dispersion states for liquid/gas flow with a targeted latency of max. 1000 ms and acquisition rate of 250 Hz;

- Develop robust and fast algorithms to extract meaningful parameters for actuator control (i.e. phase concentration, hollow vortex position, shape and size);

- Develop optimal control approach for inline flow separation process using ERT as a measurement device.

Secondments:

- Aug. 2018: Rocsole Ltd. (Finland)

- Feb. – March 2019: Teletronic Rossendorf GmbH (Germany)

- Oct. – Nov. 2019: Universidade Tecnológica Federal do Paraná (Brazil)