Controlled batch crystallization with ultrasound actuation

Fellow: Soheil Aghajanian (ESR 8)

Host: Lappeenranta University of Technology (Finland)

Main Supervisor: Prof. Tuomas Koiranen

Background:

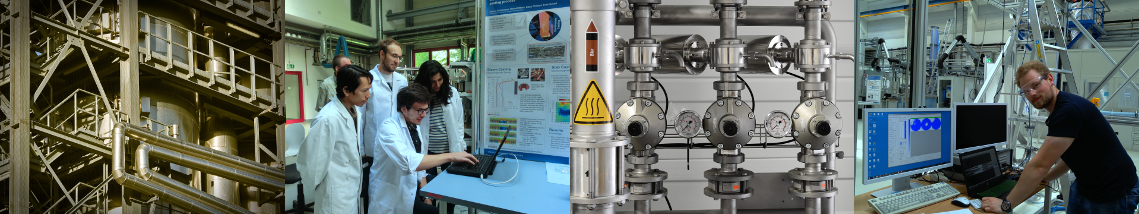

Crystallization is a widely used technique in solid–liquid separation operation, purification technique and production processes. This single process combines both particle formation and purification and is vital to many processes like manufacturing of sucrose, artificial sweeteners, coffee extracts, pharmaceutical products, petrochemical industry, etc. Hence, control over the process of crystallization in an industrial level is required to obtain products with desired and reproducible properties and avoid expensive reprocessing steps.

Process control has been in minor role in crystallization process design; an effective but under-explored way of crystallization process control is via robust tomography-based sensors and imaging instruments such as electrical resistance tomography (ERT) and ultrasound tomography (UST). Combination of Computational fluid dynamics (CFD) simulation, lab-scale tomography measurements and a feedback control system offers a new approach and a perfect solution to ensure high product quality.

The PhD candidate will develop the crystallization control system utilizing tomographic data. Different control strategies will be studied including adaptive control. The research consists of computational fluid dynamics analysis, and process modeling, as well demonstration in different scales and tomographic configurations. The project research consists of scientific analyses, engineering design and technical demonstration together with groups at universities Bath, Lodz and industry partners.

Research Activities / Objectives:

- Develop a novel multi-use lab-scale experimental set-up for tomographic measurement in antisolvent crystallization

- Devise and test first ever tomographic real-time data acquisition in lab-scale demonstrations along with product particle characterization with TUL and UOB

- Develop an adequate process modelling tool based on CFD simulation with included reaction kinetics and particle growth via population balance model

- Develop a new concept of adaptive controlling homogeneous crystal growth by ultrasound actuation

- Study potential concepts for batch-to-conti for selected fast crystallization processes achievable via tomography-based control

Secondments:

- Feb. – March 2019: Institut National Polytechnique de Toulouse (France)

- Aug. – Sept. 2019: DuPont Ltd. (Finland)

- March – April 2020: Technical University of Liberec (Czech Republic)

- April – May 2021: University of Bath (UK)